Beware of the Chlorine Bleach Scam, it can Destroy the Investment You’ve Made in your Deck!

Most people believe chlorine bleach or other sodium hypochlorite biocide based products are safe to use on modern decks.

It’s a potentially expensive belief about deck Maintenance. The Occupational Safety & Health Administration, OSHA, https://www.osha.gov/publications/shib101003, states {Under: “Use of Biocides”} “The use of a biocide, such as chlorine bleach, is not recommended as a routine practice during mold remediation, although there may be instances where professional judgement may indicate its use (for example, when immuno-compromised individuals are present.)” OSHA then states “Always, read and follow product label precautions. It is a violation of Federal (EPA) law to use a biocide in any manner inconsistent with its label direction.” Do you think it is wise for any person, employee or company, especially those that are not mold remediation professionals, to routinely recommend chlorine bleach or any sodium hypochlorite-biocide based product for cleaning mold, while ignoring products label directions, could result in problems for composite manufacturers & owners?

1st generation Trex® where the sodium hypochlorite based product originally designed & intended to clean mildew from wood has been recommended & used to clean common black mold, resulting in deep set or below the surface mold stains. Perhaps you have experienced this?

Oregon State University (OSU) has done a scientific study [CLICK HERE] titled “Ability of bleach and other biocide treatments to remove and prevent mold…(2004, April)”, has proven the specific “biocide”, “sodium hypochlorite” to be ineffective in mold remediation from the “wood”, of which most composites are partially made by concluding “Increasing bleach concentrations from 2.5 up to 20 percent {sodium hypochlorite} solution had no effect on the appearance of the wood following the wash treatment, nor did such treatments completely eliminate fungi from the wood surface. The chemical mold prevention treatments tested were not effective in sterilizing the wood, nor did they improve the visual appearance.” Even if the “visual appearance” or stains of the molds can no longer be seen, the molds will likely rapidly return if sodium hypochlorite has been used because as OSHA states; “In most cases, it is not possible or desirable to sterilize an area, as a background level of mold spores comparable to the level in outside air will persist”. “Outside air” is where most composites are located, as outside is where most composite decking & fencing is designed & intended to be installed. To summarize… Chlorine bleaching mold with sodium hypochlorite isn’t scientifically proven to kill or remove the mold from the wood of which most composites are partially made, but its use does make composites the ideal environment for the mold to thrive, especially when new mold spores in the ambient air, land on composites & receive moisture.

Mold colonized Trex® from the routine “Spring and Fall” recommendation & use of sodium hypochlorite. This deck is partially Corte-Cleaned®. The composites have been rinsed & are wet, with water to magnify the black mold stains.

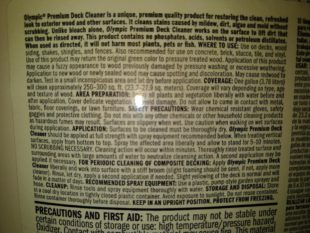

EXAMPLE: Olympic Deck Cleaner®, the most commonly recommended product for cleaning Polyethylene (PE) composites against its label directions, This products label directions from its website states “Before” with an artist rendering of a dirty weathered grey black mold stained wood deck, & “After” photo shows an artist rendering of cleaned wood deck? This products label directions state its a “DECK CLEANER”, “FOR CLEANING PRIOR TO STAINING” which claims it “Removes dirt & mildew stains”, from “wood and other surfaces”, then states, “It cleans stains caused by mildew, dirt, algae and mold”, & that this product “CLEANS UP TO 300 SQ. FT”.On the back of this products label directions, it states “Use on decks, wood siding, shakes, shingles, and fences. Also recommended for use on concrete, brick, stucco, tile, and vinyl. Use of this product may return the original green color to pressure treated wood. Application of this product may cause a fuzzy appearance to wood previously damaged by pressure washing or excessive weathering. Application to new wood or newly sealed wood may cause spotting and discoloration. May cause redwood to darken”. Vinyl is PVC plastic, not the “EARLY GENERATION PRODUCTS” PE recycled plastic known for mold problems with this composite manufacturer’s non-capped products. Then this product states “PRECAUTIONS: Do not mix with any other chemicals as hazardous fumes may result”. Such as the “soap”, “oxalic acid” or “oil stain remover”! This product then recommends being “applied at full strength” while containing “sodium hypochlorite” at “% ≥5.0 – ≤10” according to this products Safety Data Sheet, which is a greater sodium hypochlorite concentration than what Clorox recommends for “galvanized” materials almost always used to structurally support most decks.Newer packaging states “removes dirt, mold & mildew stains” with a sticker and/or new label addition that now states “ALSO FOR CONCRETE & COMPOSITE”. Keep in mind, the only “COMPOSITE” mentioned on this products label directions are “VINYL” or Poly Vinyl Chloride (PVC), not the “EARLY GENERATION” PE plastic “PRODUCTS” for which most composite manufacturers recommend this product be used. Don’t believe this, go read this products label directions or its competitors that contain sodium hypochlorite!

Most composite manufacturers have chosen to ignore OSHA & science by routinely recommending sodium hypochlorite-biocide based products on a Spring and Fall basis against these products label directions. Why would they do this? Most composite manufacturers have stated to us, they wanted the mold problem to appear to rapidly go away, to eliminate furious customers & expensive warranty claims with cleaning products that were readily available locally at most retailers, have a low perceived price point & which are generally accepted by the uneducated public for cleaning mold. Other composite manufacturers have stated they are in the business of making money. Could it be that the routine recommendation of scientifically unproven sodium hypochlorite, which almost guarantee the rapid return of molds & other fungi, & routine purchase of these cleaning products, is better for the composite manufacturer & retailer bottom line profits, especially if they are getting a financial kick-back for recommending them?

The same Mold stained Trex® deck which has been partially Corte-Cleaned®. The deck is dry. It is best to only apply or re-apply Corte-Clean® to thoroughly dry composites. Failure to apply or re-apply Corte-Clean® to thoroughly dry composites is the #1 reason our proven product fails, especially if neglected or previously cleaned with sodium hypochlorite until completely colonized with mold stains. Notice how approximately a 10 Sq. Ft. section is being cleaned. This generally saves time, labor & money while preventing dirty Corte-Clean® from drying in the composites resulting in difficult to remove stains.

Most composite owners trusted the composite & chemical manufacturer, along with retailer cleaning chemical recommendations, for routinely cleaning common molds that contains “sodium hypochlorite” because it generally intitally appears to rapidly bleach out the mold stains. Most composite owners initially think sodium hypochlorite-based products “work great”, the first several times these products are routinely used. Don’t be fooled, the routine use of any sodium hypochlorite-based products almost always further exacerbates common mold problems, by generally making the molds more resistant to the chlorine in these products, especially if diluted or low sodium hypochlorite concentrations are initially used, while the water in these products, waters the molds, helping the mold & other fungi immediately re-grow, especially where mold spores exist, resulting in its rapid return, generally within days or weeks, which has infuriated composite owners, plaguing the composite industry & tarnished its overall reputation.

Trex® Black Mold Stained (left of picture) from the routine Spring and Fall recommendation of a sodium hypochlorite based product intended to clean wood of mildew & Corte-Clean® cleaning (right of picture).

A common example would be for composite owners to generally start with a 3% to 6% sodium hypochlorite-based laundry bleach, after reading composite manufacturer cleaning literature, because it contains the composite manufacturer recommended “sodium hypochlorite” for cleaning “Mold and Mildew”. Most already own it & it is the cheapest product that contains sodium hypochlorite. When this generally fails, owners tend to generally work their way up in price & sodium hypochlorite, as the lower-priced, lower sodium hypochlorite strength products have less & less of a chlorine bleaching effect or result in rapid return of fungi when composites receive moisture. When these products generally fail in bleaching the mold, or mold rapidly returns, most then choose products with a higher sodium hypochlorite concentration & price point, such as outdoor bleach. These products are generally a little more expensive & contain 6% to 7% sodium hypochlorite. These products too generally initially seem to work by bleaching out the molds, but most eventually generally notice the molds never really going away, especially when composites are wet, with water, and/or rapidly returning when composites receive moisture.

Elk Cross Timbers® made from PE plastic & recycled wood where the black mold is no longer spotting but completely colonizing this composite deck! This is a result of the routine use of a sodium hypochlorite-based product originally designed to clean “wood” of “mildew”! Notice: no white silky looking wet living mildew or dry white dead looking powdery mildew. Where the BBQ mat was blocking mold spores & moisture, notice no black stains.

When these products fail, composite manufacturers then generally recommend products that contain 5%+ sodium hypochlorite & more volatile surfactants, which may not be biodegradable and/or polluting phosphates, which can act as fertilizers such as Miracle Gro® for helping mold & other fungi to rapidly grow or re-grow, especially polluting algae in water! One composite manufacturer recommends a cleaning product for mold, to clean their PE plastic & maple hard-wood composites that contains sodium hypochlorite & a phosphate, which is intended to only clean “vinyl” PVC plastic & “wood”, as stated on this products label directions, even though this products “Frequently Asked Questions”, “Can I use {this companies} Cleaner on composite decking?”, & answer; “Yes, {this companies} Cleaner works great. Follow the directions on the label”. Composite manufacturer recommendations of cleaning chemicals, to be used against these product label directions, to clean plastics of fungi not stated on these products label directions has resulted in an absolute nightmare for composite owners.

Trex® where the most commonly recommended “sodium hypochlorite” based product originally designed & intended to only clean “wood” of “mildew” was routinely recommended to be used “Spring & Fall”, for years, until completely colonized with common black mold. Notice how the mold is no longer spotting, but is growing together & has completely taken over the boards. This is a worst-case scenario, especially since this deck was not properly installed, with proper gaping, in-between boards, to allow water to easily drain. Notice the red rust corrosion stains around the fasteners! What about the structural metal nails & joist hangers under the deck that can’t be seen?

When the low-cost sodium hypochlorite-based products generally ultimately fail in routinely bleaching common molds, and/or result in rapidly returning fungi, customers then generally contact composite manufacturers to complain & file a warranty claim. Composite owners are then generally referred to special cleaning instructions & products for mold & mildew, such as a “Mold Technical Bulletin” PDF. Sometimes, the manufacturers send an employee, such as an untrained sales representative to clean the composites of molds with sodium hypochlorite-based specialty product(s), to show owners how easy it is to clean composites with these products. One chemical & composite manufacturer recommend & sold a chlorine based chemical commonly used to treat water of algae in swimming pools while others sold products to be dangerously/illegally mixed with chlorine bleach! Composite manufacturers then generally recommend that owners routinely only use these more expensive products moving forward, which are generally only available over the internet, and still aren’t even close to the “20%” sodium hypochlorite concentrations which OSU has proven to be scientifically ineffective for mold remediation while ignoring OSHA recommendations?

Trex® where the more expensive “Mold Technical Bulletin” & “MUST be used within 30 days” sodium hypochlorite-based specialty composite deck cleaning product was recommended to be routinely used “Spring and Fall” until it became completely mold colonized with common black & green molds. The owner that sent us this picture was routinely spending a fortune purchasing on the internet & laboriously using this product, watching these fungi getting worse & worse with each routine application

The previous routine use of any sodium hypochlorite-based product almost always results in sterilizing everything but the molds biofilm, especially in porous composites. The water in the sodium hypochlorite-based products, waters the fungi, generally resulting in its rapid immediate re-growth, especially in sunny moist humid routine moisture conditions. Semiannual routine “Spring and Fall” use of any sodium hypochlorite-based products, at any sodium hypochlorite strength, generally ultimately results in visible mold stains never being fully bleached out, especially when composites are wet, with water, as water generally magnifies the fungi or biofilm on/in composites, but only temporarily dulls the color of the mold by bleaching, as the molds become more & more resistant to the chlorine in sodium hypochlorite-based products. This is very much like routinely improperly using penicillin for common viral infections till it becomes ineffective. Eventually, the mold completely colonizes entire boards resulting in a worst-case scenario & common sodium hypochlorite-based products have little if any bleaching effect. Perhaps you have experienced this?

Trex® completely colonized with black & green mold where sodium hypochlorite was routinely recommended to be used for 15 years. This is another example of a worst scenario, especially because red corrosion stains can be seen around the fasteners! What does the non-visable structural metal decking hardware look like that can’t be seen? Could the routine use of corrosive cleaning chemicals be a safety issue to unsuspecting composite deck owners?

Most don’t realize the routine use of sodium hypochlorite-based products generally further exacerbates mold problems. Routinely using scientifically unproven sodium hypochlorite-based products for cleaning composites of common mold stains generally results in the needed to expensively purchase & laboriously routinely use these & other products more & more frequently, costing more & more time, labor & money. The recommendation & routine use of sodium hypochlorite to clean mold is the #1 issue in the composite decking industry.

Trex® decking which has been routinely chlorine bleached in an attempt to clean mold for over 13 years with a sodium hypochlorite based product as was recommended by the Trex® Company. This is a worst case scenario! Corte-Clean® will clean it, but it will cost more time, money & labor. Corte Clean will likely restore some of the original weathered color too. The alarming issue is the corrosion sodium hypochlorite can cause to the structural metal decking hardware!

The use of sodium hypochlorite-based products generally does excessively chlorine bleach the color of almost all composites, especially when used to clean PP & PE plastic, at higher strengths, undiluted & in direct sunlight, when most people clean composites. Sometimes composites turn yellow from the chlorine. This is because most sodium hypochlorite-based products were generally designed to clean only “wood” and/or “vinyl” PVC plastic which about 57% of the mass is made from chlorine. Composites, especially those made from recycled PE plastics, which were generally colored after the plastic was made, are generally more easily chlorine bleached beyond what is disclosed under “weathering”, or fading, by some composite manufacturers, especially when using products that contain higher concentrations of sodium hypochlorite, undiluted, and/or more volatile surfactants that clean the color out. This generally leads to the 2ndbiggest complaint in the composite industry, excessive color fade by chlorine bleaching with sodium hypochlorite.

Why Chlorine Bleach or other sodium hypochlorite based products is Not Smart for Cleaning Composites!

Corte LLC freely admits that sodium hypochlorite based products generally appear to quickly bleach out mold, on most composites, the first several times used. Don’t be fooled! The following photo is an example of what a composite deck looks like when sodium hypochlorite, the active ingredient in chlorine bleach, and common deck cleaners generally designed to clean “wood” of “mildew”, which is not common on composites, has been repeatedly used. Notice how the sodium hypochlorite no longer bleaches out the mold stains. Notice how the composites are turning solid black, and no longer spotting, becoming deeply rooted and infested in the composite, while it feeds off of the tannin from exposed wood fibers. The sodium hypochlorite sterilizes the composite of everything except the mold, making it a perfect environment for mold spores to grow when they receive moisture. Perhaps this explains why so many composite manufacturers that have routinely recommended chlorine bleach or other sodium hypochlorite based cleaners for cleaning common black mold, have ended up with so many unhappy customers. The left side of the below photo shows how water magnifies mold stains, which have been exacerbated by the routine use of products containing sodium hypochlorite. The below photo shows how Corte*Clean® will clean these stains when sodium hypochlorite no longer bleaches out the mold stains. This photo represents a classic example of why sodium hypochlorite should never be recommended or used to clean composites of mold stains.

Left side of picture shows a mold stained composite deck exacerbated by the previous routine use of sodium hypochlorite. Right side of Photo shows Corte*Clean® cleaning this deck.

Sodium Hypochlorite is scientifically proven to exacerbate mold issues. This is why those that ignore science, & recommend or use sodium hypochlorite to clean mold, generally experience the rapid Return of mold stains! This is the #1 complaint in the composite decking industry.

Why sodium hypochlorite isn’t smart for mold cleaning.

-

- Kills plants grass surrounding composites.

- Off-Gasses chlorine smell when used and after being used.

- Causes Corrosion to Structural Metal Fasteners & Connectors, the #2 biggest issue in the decking industry, which leads to rust stains around metal fasteners, such as screws or nails which is expensive to remove with another cleaning product, which is not compatible with sodium hypochlorite.

- Need to purchase and use other expensive products for specific stains such as grease, oil, rust, tannin stains, etc. which are not compatible with sodium hypochlorite.

- Doesn’t eliminate “tannin bleeding” which can feed funguses such as mold.

- Scientifically proven to exacerbate mold issues, resulting in its rapid return, leading to the #1 complaint in the composite decking industry.

Composite cleaned with chlorine bleach.

Chlorine bleached. The composite is still wet after being rinsed with water. See the black mold stains?

Same composite deck approx. 2 weeks later. Composite is dry. See the mold returning?

Same composite deck. Composite is wet with water. Water magnifies stains on composites.

Same composite deck after being Corte Cleaned! Composite is wet with water.

Here is a testimonial/review of a sodium hypochlorite based product that proves the point by a composite deck owner, however, this deck likely doesn’t have “mildew” but rather common black mold stains.

JimC – Review provided by Lowes (through Google Shopping)

I have Trex decking. I have to clean it once or twice a year to get rid of mildew spots, which are getting worse and worse and harder to deal with. The folks at Trex recommended the [sodium hypochlorite] product. It made the spots better, but certainly didn’t get rid of them. I still have a “leopard pattern” deck.

Perhaps it is because this product was originally designed and labled to clean “wood” of “mildew”, not plastic/wood composites of common black mold stains?

Trex® with mushrooms attached to the wood fiber & feeding off the tannins. Failure to thoroughly Corte*Clean® the wood of which most composites are partially made of tannins, to eliminate “tannin bleeding” feeds funguses. This deck had only been previously cleaned with sodium hypochlorite.

Trex® decking, only cleaned with SODIUM HYPOCHLORITE FOR 15 YEARS. Not only is it MOLD INFESTED but notice the CORRODED SCREWS! It doesn’t take a genius to know that ignoring metal decking hardware manufacturer disclosures of “corrosion risks” of “cleaning chemicals” isn’t smart! If yours look like this, PLEASE have your decking inspected for corrosion by a professional and replaced if necessary.

Trex® decking, only cleaned with SODIUM HYPOCHLORITE FOR 15 YEARS. Not only is it MOLD INFESTED but notice the CORRODED SCREWS! It doesn’t take a genius to know that ignoring metal decking hardware manufacturer disclosures of “corrosion risks” of “cleaning chemicals” isn’t smart! If yours look like this, PLEASE have your decking inspected for corrosion by a professional and replaced if necessary.